How to Select a Laser Diode Controller

Tips to Selecting the Best Controller for Your Application

WHAT IS A LASER DIODE CONTROLLER?

A laser diode controller consists of a constant current source combined with a TEC (thermoelectric) temperature controller. They provide stable current to a semiconductor laser and they control the laser diode's temperature. They provide both functions. A laser diode driver usually just refers to the bias current source and typically does not include the TEC controller. A laser diode controller includes an integrated low noise current source to bias the laser as well as an integrated bi-polar current source for the peltier cooler which controls the laser's temperature. Both of these functions are combined into one instrument or module.

A high quality laser diode controller should be selected for the intended application of the laser and the required current / TEC power. But the budget for the project is also a top selection factor. So we have put together a few very affordable options that also offer the highest levels of quality and protection for your semicondutor laser. Also, choosing the best controller options from multiple brands is time consuming. In addition to over 35 manufacturers of controllers for diode lasers, prices vary widely and ther are multiple form factors such as benchtop, OEM and PCB mount. Hopefully the short list of affordable controllers shown below will save you some time. But if you want to shop laser diode controllers from all manufacturers », visit our Laser Diode Controller Selection Guide and use the filters to find the best product for your application.

SHOP FEATURED LASER DIODE CONTROLLERS:

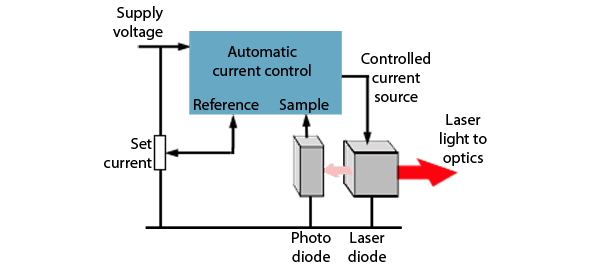

INTEGRATED CURRENT SOURCE (DRIVER):

We won't go too deep into the bias current source (driver) portion of the controller. To get detailed information on the driver portion, please read Laser Diode Driver Fundamentals. The constant current source in a controller is independent of voltage (ideal current source). Key features typically include low noise, stable output current over time, and protection for the laser diode in the form of current limits, slow start circuits, and transient and surge protection among others.

INTEGRATED TEC CONTROLLER:

The laser diode temperature controllers is typically referred to as the TEC (thermoelectric cooler) controller. It's function is simply to source a bi-polar current to a device known as a peltier element to remove the heat generated by the laser. Peltier controllers are fairly complicated devices on their own. If you want a more complete description you can read "Controlling the Temperature of Laser Diodes". Fundamentally, the temperature controller is a bipolar power supply which also has the ability to measure electric signals from temperature feedback devices such as thermistors (temperature proportional to resistance), or solid-state devices such as AD590 (temperature proportional to current) and LM335 (temperature proportional to voltage) sensors as feedback for a control loop. They take the feedback signal and supply power to the peltier device. It's important to note that they can be over-driven with current. Therefore, another feature common in laser diode temperature controllers are output current limits. Rounding out the feature set common in these devices are programmable PID control loops, some of which have auto-tuning capabilities. If you want to learn more about TEC Temperature Control and you have ~ 20 minutes there is a great video overview of TEC theory and temperature controller design below.

FACTORS WE USED FOR OUR RECOMMENDATIONS:

Before we list the technical criteria used in determining the recommended controllers referenced above, we should mention that everyone on our staff is either an electrical engineer or a physicist with over 10 years of experience working with semiconductor lasers. Our recommendation process includes an in-depth review of 9 different key attributes for each product:

- 1. The number of laser diode protection features and the quality of the specification associated with each feature.

- 2. The availability and quality of documentation to back-up each of the specified protection features.

- 3. The RMS noise and ripple value and the noise density plot in the frequency domain.

- 4. The availability and quality of documentation to back-up the specified noise and ripple values.

- 5. The TEC control loop algorithm and user access to adjusting the proportional, integral and derivative portions of the control loop.

- 6. Set point resolution and accuracy for the LD bias current and the TEC control parameters.

- 8. Availability of LabVIEW drivers or control software when a PC interface is available.

- 7. Quality of the Operating Manual and support documentation

- 8. Reputation and core focus of the manufacturer as well as the number of years the manufacturer has been in business.

- 9. Price and availability.

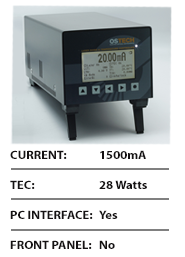

BENCHTOP INSTRUMENTS:

Designed for the laboratory, benchtop controllers generally include a front panel with control knobs and buttons They offer an integrated AC to DC power supply and standard d-sub type output connectors. They are typically easy to setup and start using. Other common features often include a multi-range output, low noise (isolated power suppliers, shielded chassis), and computer interface. Price range: $1,500 to $4,000, shop products »

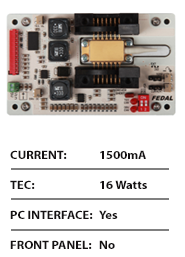

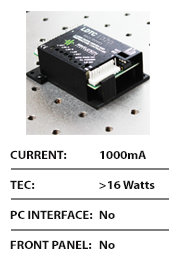

OEM PRODUCTS:

For applications requiring integration into a laser system or for a limited budget project, OEM products offer a cost effective solution. Setup is more complicated than a benchtop instrument and you will need a separate AC/DC power supply. But these compact products are ideal for users who need easy integration into a larger system. They are available in a wide range of output current ranges, 50 mA ‑ 100 Amps with TEC power up to 150 Watts. Price range: $100 to $1500, shop products »

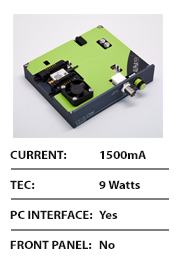

HYBRID CONTROLLERS WITH INTEGRATED MOUNTS:

Designed for both OEM and laboratory applications, this type of product features an integrated butterfly mount heat sink. These laser diode controllers are designed for low power butterfly packaged devices with output currents up 1.5 Amps. These units are typically computer controlled and use an external AC/DC power supply. Ideal for laboratory applications with limited space or integration into larger laser systems. Price range: $500 to $2,500, shop products »

REMOTE CONTROL FOR AUTOMATED APPLICATIONS:

Referred to in the industry as remote interfaces, conntrollers can be controlled externally. Set-points for the current level or temperature, output on / off and system error monitoring can be done from a PC or DAQ unit. This is accomplished usually from a computer with either an analog I/O (input/output) card or through a digital interface such as GPIB, USB, or RS-232. The instruments and devices will usually come with a command list and/or drivers which the programmer will incorporate into the system control software.

SUMMARY: SELECTING THE BEST LASER DIODE CONTROLLER:

We recommend that you start with the output current maximum range and the compliance voltage range for the device you will control. Then choose the temperature controller output power. Keep in mind that the current source output accuracy and resolution are a function of current range, so you don't necessarily want the highest possible range. For example, a current source with a 2A range, has a resolution (smallest step) of 40 µA, while in an instrument with a 200 mA range, the output current resolution is 2 µA (where a 16 bit DAC is employed). On the TEC controller side you will need to understand the thermal load characteristics of your application, then choose the output power of the temperature controller appropriately. A 16W temperature controller will not provide the power to control the temperature of a 32W thermal load. This will most liekly result in thermal run-away and possibly destroy the laser. Finally, decide if you need a remote interface and start looking at the protection features listed for the model you are considering.