Home > Laser Diode Heat Sinks & Mounts > ETE > OCP-050A / LASER-DIODE-HEAT-SINK

Advanced Thermal Design Dissipates up to 50 Watts of Heat; High Performance LASER DIODE Mount & Heat Sink Assembly

$425.00 sku / item#: OCP-050A / LASER-DIODE-HEAT-SINK ships: In-Stock (USA)

Key Features

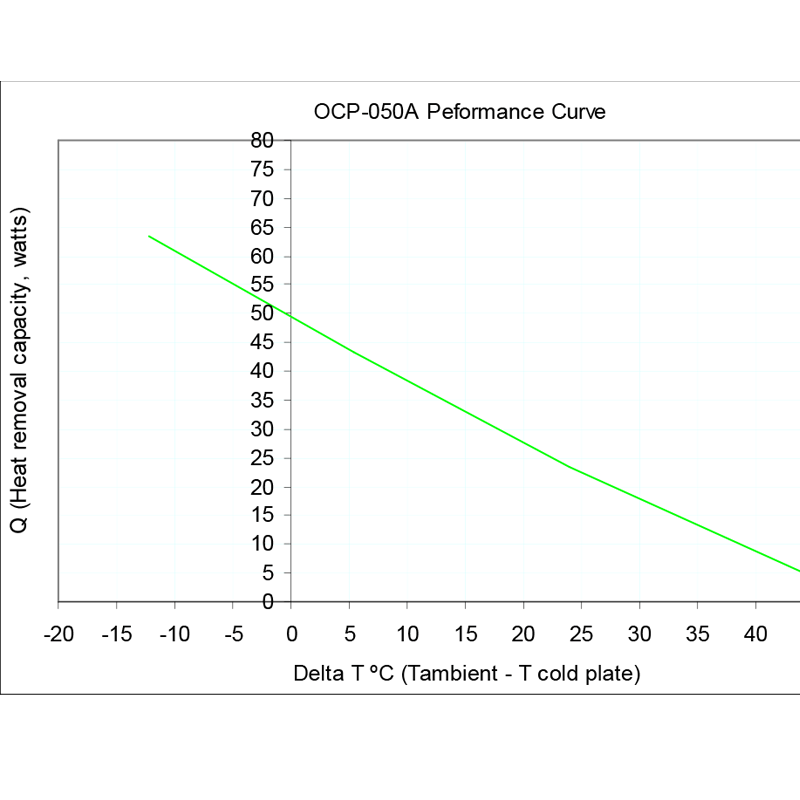

- 2 x Integrated TE / Peltier Coolers and Fan offer Advanced Thermal Control and up to 50 Watts of Laser Waste Heat Removal

- Laser Diode Mounting Plate Pre-Configured for your Specific Laser Diode ($80.00 option)

- Thermal Resistance ~ TEC to Ambient 0.22ºC/W

- Optimized for 808nm, 915nm, 940nm, 976nm and 980nm Pump Lasers Emitting 1W ~ 50W of Laser Output Power

Product Warranty

All products purchased from Laser Lab Sourceare sold with a full one-year warranty. See terms & conditions for full details.The Laser Lab Source group websites include:- LaserDiodeSource.com

- LaserLabSource.com

- LaserDiodeControl.com

Price and Delivery Quote

Buy Now / Add to Cart

Customers Also Considered:

| MODEL | OCP-050A / LASER-DIODE-HEAT-SINK |

|---|---|

| PRICE | $425.00 |

| mount and heat sink assembly OVERVIEW | |

|

|

| Connections | |

|

|

| INTEGRATED FAN AND TEC RATINGS | |

|

|

Product Overview:

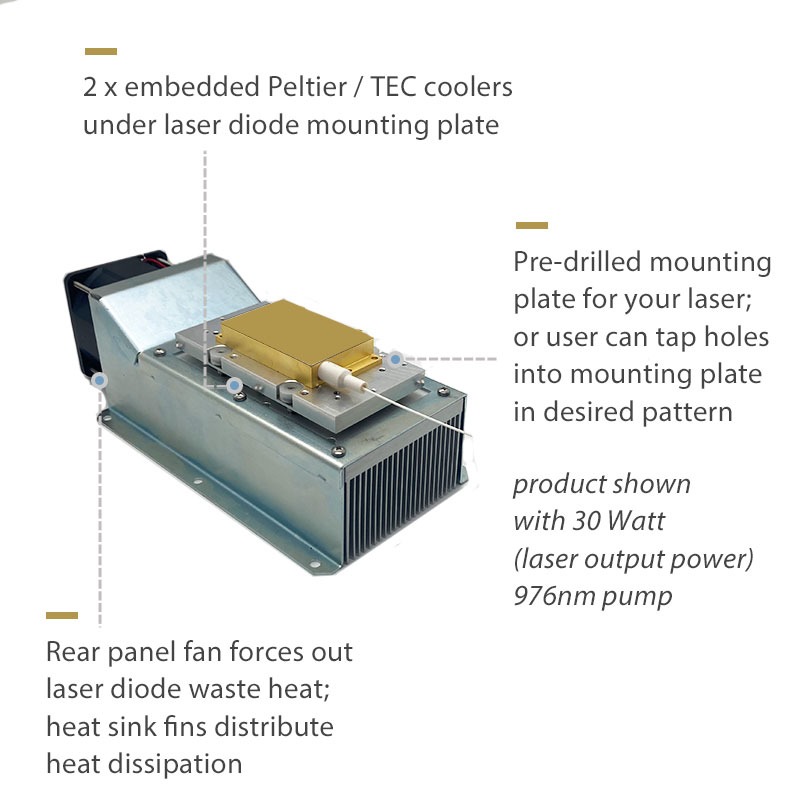

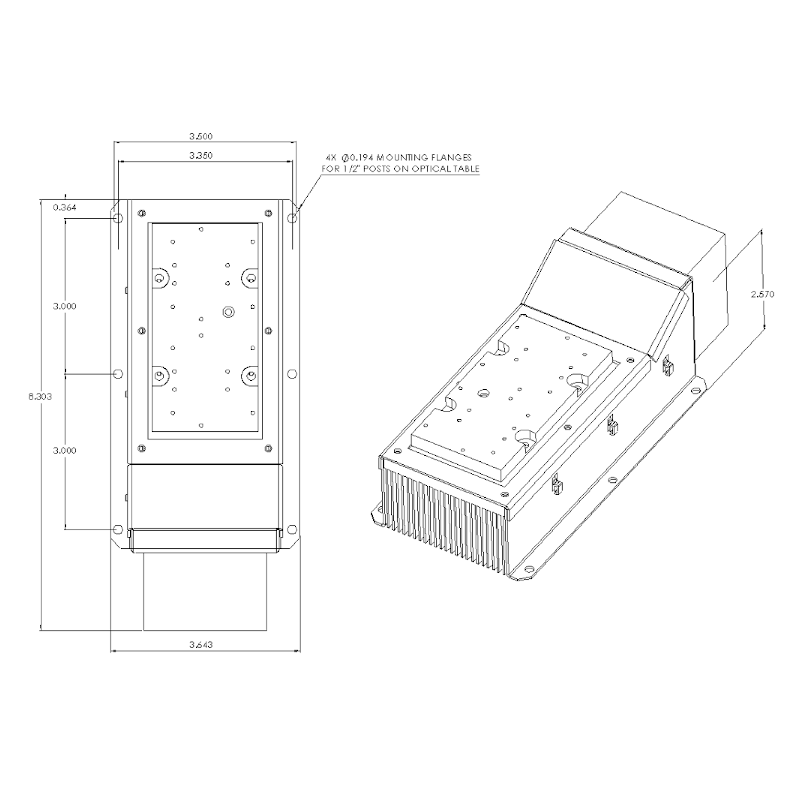

50W Advanced Performance Peltier and Fan Cooled Laser Diode Heat Sink

The laser diode mounting plate comes with pre-drilled holes which you can use to screw your laser diode into the mounting plate; or you can drill your own mounting holes for your laser diode package in the mounting plate ~ or order this product with the mounting plate Pre-Drilled at the factory for your laser package for an additional $80.00; this versatile laser diode heat sink and cooling module has been optimized for lasers with optical output power up 50W. It is commonly used to actively cool 808nm, 915nm, 940nm, 980nm fiber-coupled pumps. Dual embedded high efficiency TEC's and a fan provide high temperature stability and precise temperature control. The standard air flow direction is pushing air thru the heat sink; an option is available to pull air from the front of the heatsink. The fan is configurable to allow a user to remove the fan and change the direction of the air flow as desired. This allows the user to optimize the performance for the ambient air flow conditions in the lab.

Heat Sink Cooling Design Details

The mounting base for the laser diode is temperature controlled by Peltier / TEC coolers. The maximum operating current for the TE cooler is 4.2 amps with a maximum voltage draw of 12 volts DC at room temperature. The current and voltage required for the TE cooler will increases as the temperature of the lab increases. The user should not exceed the maximum specified current. Exceeding the maximum power ratings will reduce the performance of the TE cooler and reduce its reliability. The typical current required for each of the TEC's is in the 3 to 4 amp range. This will vary due to the desired temperature set point and the heat load. The interface quality between the laser diode and the heat sink also contributes highly to the performance of the unit. For high power laser modules with large footprints, it is recommended to use a thermal compound or a phase change material to facilitate the heat dissipation through the laser package into the heat sink. Users are advised to manually adjust the current to the TEC after attaching the diode to the top plate. This will allow the user to identify the optimum current and set the current limit on the TEC controller appropriately. All of the Peltier modules used are environmentally sealed to allow operation below dew points. The cold plate is made of anodized aluminum alloy.

Why do Scientists & Engineers Choose Laser Lab Source?

-

Get DIRECT, Fast Tech-Support from the Product Engineer, No Sales Person in the Middle

-

Get the Lowest Price, Factory Direct, No Mark-Up's, Suppliers Post their Own Price

-

Get a 30 Day Evaluation Period with No Risk Return on Most Products, Check Availability