Home > Laser Diode Controllers - (Driver + TEC) > Maiman Electronics > MBL1500A

$2622.00 sku / item#: MBL1500A ships: Request a Quote for Current Ship Date

Key Features

- All-In-One Low Noise Laser Diode Driver, TEC Controller and 14-Pin Butterfly Mount

- 4-LEVEL Advanced Laser Diode Protection:- Soft-start current ramp to set-point- Current & temperature limits- Dual stage over-temperature limits- Power surge & ESD transient shunt circuit

- Front Panel Control Using Touch Screen or Key Pad

- Remote Control by USB (GUI Software and Communication Protocol included; LabVIEW Drivers; Python)

- Compatible with Type 1 and Type 2 butterfly 14-pin Laser Diodes

Product Warranty

All products purchased from Laser Lab Sourceare sold with a full one-year warranty. See terms & conditions for full details.The Laser Lab Source group websites include:- LaserDiodeSource.com

- LaserLabSource.com

- LaserDiodeControl.com

Price and Delivery Quote

Buy Now / Add to Cart

Customers Also Considered:

| MODEL | MBL1500A |

|---|---|

| PRICE | $2622.00 |

| CURRENT, VOLTAGE & TEC CONTROLLER | |

|

|

| LASER DIODE PROTECTION | |

|

|

| DIMENSIONS AND WEIGHT | |

|

|

| USER INTERFACE | |

|

|

| POWER SUPPLY INPUT | |

|

|

| WARRANTY PERIOD | |

|

|

Product Overview:

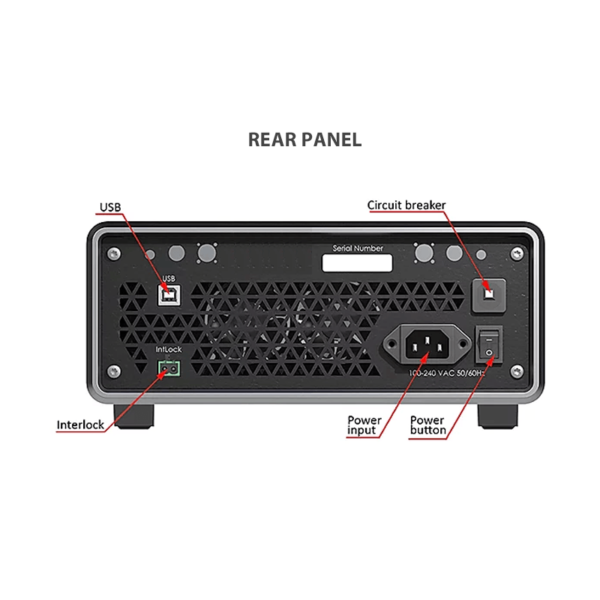

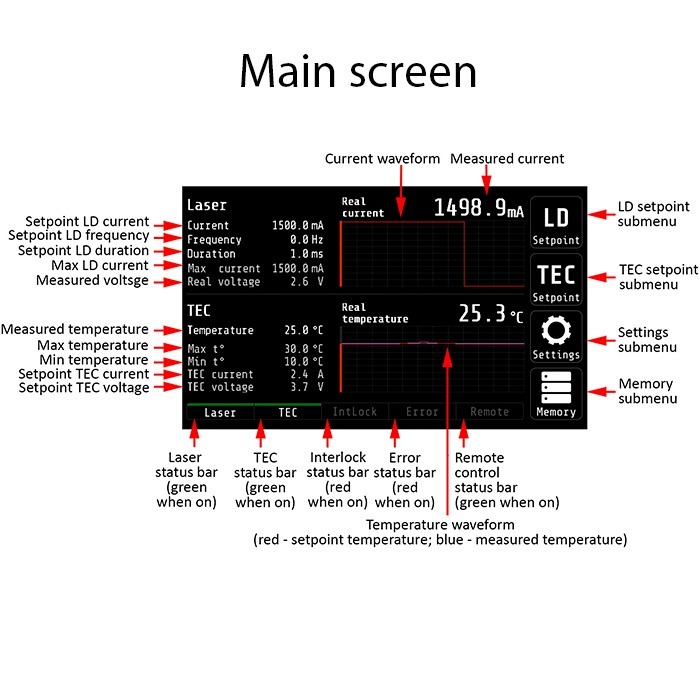

Integrated Low Noise Benchtop Laser Diode Driver + TEC Controller + Butterfly Mount The MBL1500A hybrid laser diode control electronics and butterfly package mount instrument offers an all-inclusive, high performance solution for controlling butterfly packaged laser diodes. These controllers are an excellent choice for laboratory test applications. Key features of these instruments include a low noise laser diode current source to safely electrically bias your laser diode, an integrated TEC / temperature controller and a 14-pin butterfly package mount. They also include multiple control interface options to enable you to control all of the parameters of your laser diode. Interfaces include a touch panel front panel display, a front panel key pad, a USB with Control Software GUI / Virtual Front Panel, LabVIEW and Python code libraries. ---------------------------------------------------------------------------------------------- MULTI-LAYER LASER DIODE PROTECTION: 1. User Adjustable Current and Temperature Limits The user can set current limit and temperature limits to ensure safe operation and a long lifetime for your laser diode. 2. ESD Protection and Power Surge Protection Circuit An integrated crowbar circuit protects the laser diode from power surges, ESD, and damage to the laser diode from brown-out or black-out events. An integrated on-board zener diode in parallel with the bias current path protects the laser diode from damage which can occur from reverse voltage transients. These transients can occur when a standard DC power supply source is momentarily interrupted due to a black-out or brown-out power outage. Additionally, these module ship with a jumper clip that shunts the laser diode bias current path of the driver to protect the laser from ESD or static discharge when the user is installing the laser into the mounting socket. This shunt also protects the laser when the user is connecting the DC power or any other external equipment. 3. Soft-Start Current Ramp There is an internal 500 millisecond soft-start ramp to the current set-point. This reduces the potential for thermal shock to the laser at power ON and is used to ensure good electrical contact prior to fully applying the current bias the laser diode. 4. External Over-Temperature Monitor Input Primarily designed for integration of the module into a laser system, an additional thermistor input is provided to allow the user to monitor the temperature from an external measurement point. This can then be used to shut the laser diode off if a temperature maximum for the system is exceeded. ---------------------------------------------------------------------------------------------- Constant Current Source Laser Diode Driver The MBL series controllers are based on high stability, low-noise current source topology to ensure optimal performance from your laser diode. They provide exceptionally low drift, allowing for consistent and repeatable results. The constant current source topology is based on a precision sense resistor which is placed in series with the laser diode. The voltage across this sense resistor is fed into a differential amplifier, which compares it to the reference voltage. If the measured current deviates from the setpoint, the feedback loop adjusts the control voltage applied to the pass transistor (MOSFET). The transistor acts as a variable resistor, dynamically adjusting to maintain the desired current. The current source automatically adjusts its output voltage to meet the laser's requirements while keeping the current constant. Integrated TEC Controller The integrated TEC controller with a full P.I.D. control loop prevents overheating of the laser diode and is designed to reduce thermal fluctuations. Precise thermal stabilization ensures consistent laser output without drift. The TEC control loop provides millidegree temperature stability and can quickly stabilize high heat loads to reduce the risk of damage to your laser. User adjustable upper and lower temperature limits can be programmed to protect the laser diode and the Peltier device. Additionally, TEC output current limits are user-configured to protect the Peltier device from over-drive damage.

Why do Scientists & Engineers Choose Laser Lab Source?

-

Get DIRECT, Fast Tech-Support from the Product Engineer, No Sales Person in the Middle

-

Get the Lowest Price, Factory Direct, No Mark-Up's, Suppliers Post their Own Price

-

Get a 30 Day Evaluation Period with No Risk Return on Most Products, Check Availability