Home > Laser Diode Controllers - (Driver + TEC) > OsTech > LDC-578X

$4345.00 sku / item#: LDC-578X ships: 14 to 18 days

Key Features

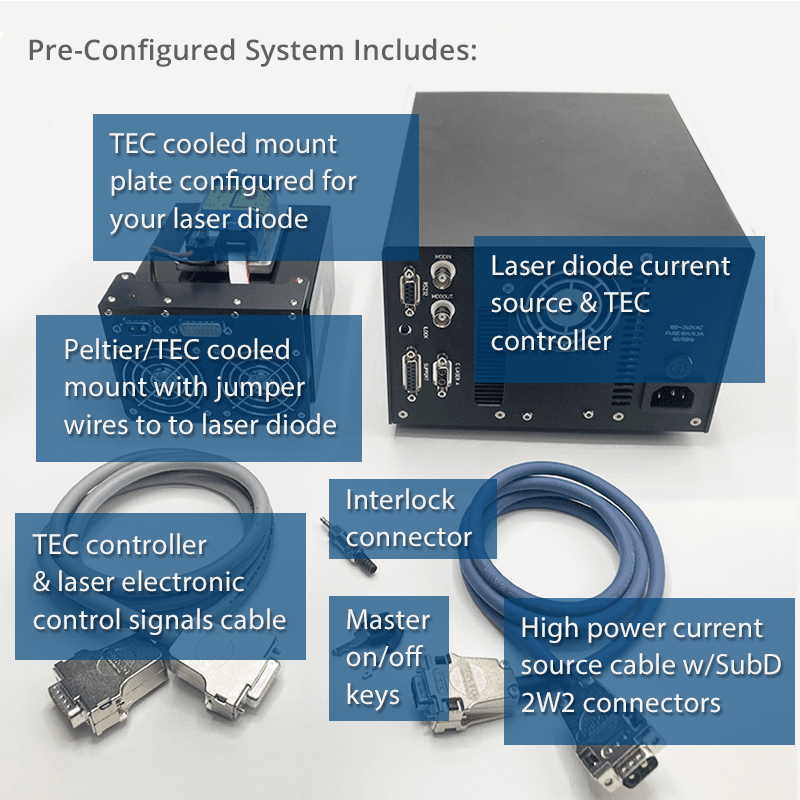

- All-Inclusive Control System with Laser Driver, TEC Controller, Mount, and Cables

- CW and QCW Pulsed Modes of Operation

- Models Available for Most Package Styles

- RS232 Interface with LabVIEW Drivers; USB Optional

Product Warranty

All products purchased from Laser Lab Sourceare sold with a full one-year warranty. See terms & conditions for full details.The Laser Lab Source group websites include:- LaserDiodeSource.com

- LaserLabSource.com

- LaserDiodeControl.com

Price and Delivery Quote

Technical Questions for this Product

ASK AN ENGINEERCustomers Also Considered:

| MODEL | LDC-578X |

|---|---|

| PRICE | $4345.00 |

| LASER DIODE DRIVER (CURRENT SOURCE) | |

|

|

| INTEGRATED LASER DIODE PROTECTION FEATURES | |

|

|

| TEC CONTROLLER | |

|

|

| MOUNTING PLATE, HEAT SINK & CABLES | |

|

|

| MODULATION & QCW PULSE MODE | |

|

|

| CONTROLLER COMPUTER INTERFACE | |

|

|

| POWER SUPPLY, WEIGHT AND DIMENSIONS | |

|

|

Product Overview:

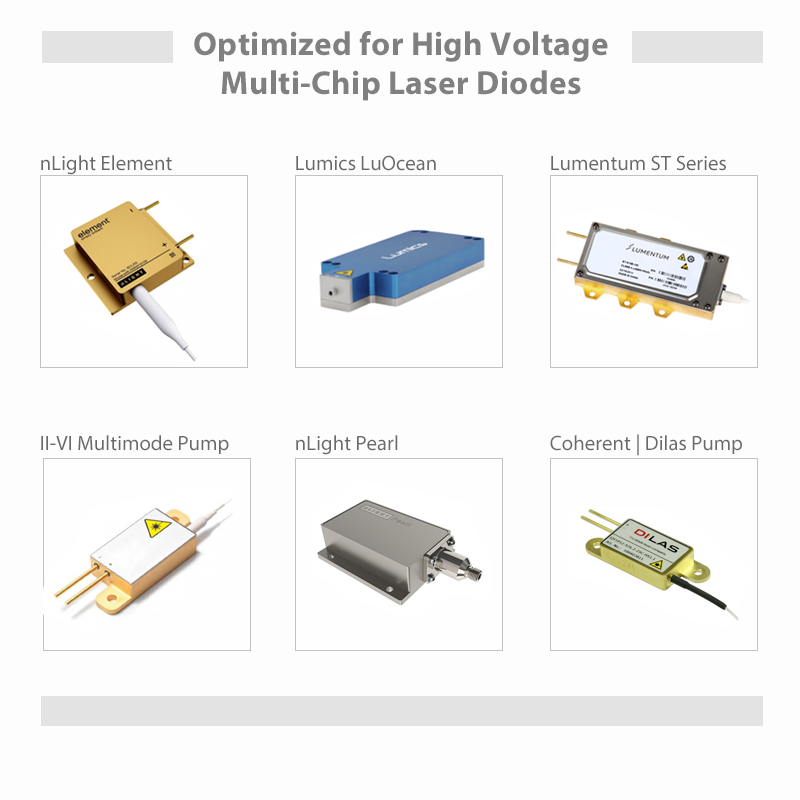

Laser Diode Control System for Laser Diodes with 10 Watts to 100 Watts Output Power

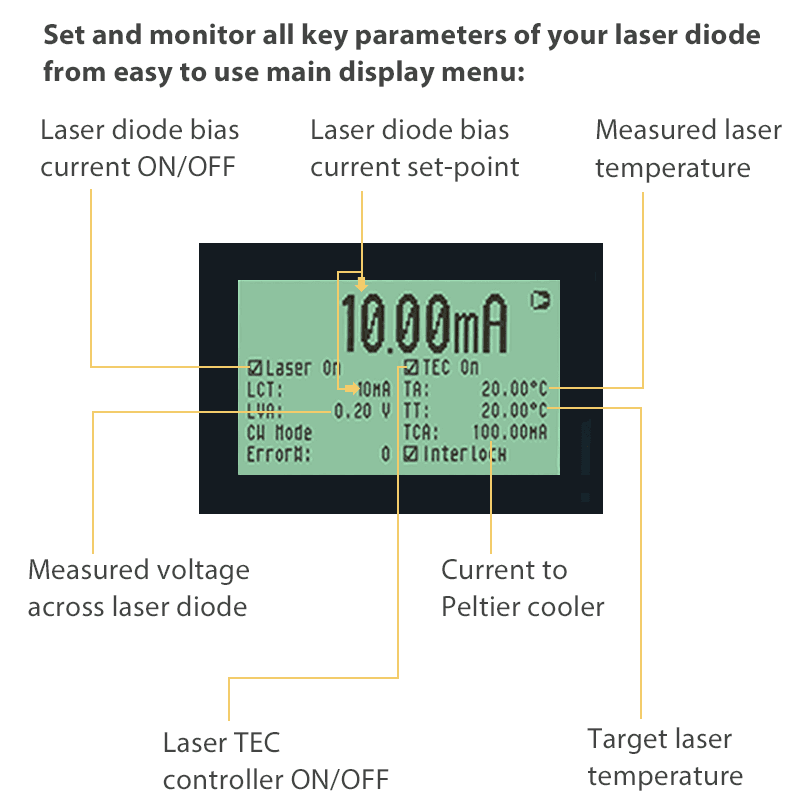

The model LDC-578X control system was designed to accurately and safely control high power pump laser diodes which emit optical power in the range of 10 watts to 100 watts. These systems include everything you need to bias and thermally control your high power pump laser diode. They integrate a precision 14 Amp laser diode driver, a 216 Watt TEC controller, a TEC cooled laser mounting plate, a fan cooled heat sink and all cables. The > 200 Watt temperature controller keeps the laser at a stable temperature while allowing the user to drive the laser in CW or QCW mode at bias power levels up to 14 Amps and 20 Volts.

Protection Features for High Power Laser Diodes

The driver includes laser diode protection features such as current limit, soft start current ramp, and power surge filters to make sure that your laser diodes are protected at all times. The soft-start current ramp is pre-set at the factory to 300 milliseconds, but is user-adjustable. This current ramp-up and ramp-down function is designed to protect the laser from thermal shock during power-up and power-down sequences.

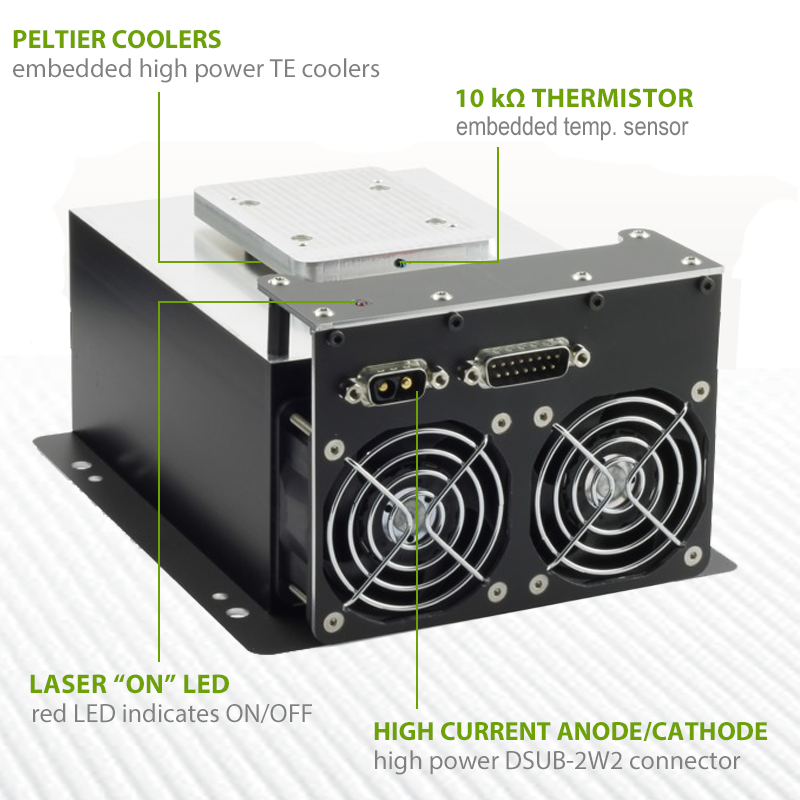

Pre-Configured Mounting Plate for your Laser Diode

These control systems come with a Peltier / TEC cooled mounting plate which is configured for your specific laser diode package. The mounting plate holes are drilled to the module footprint and all of the interconnect cables are terminated for your laser's pin diameters. Simply submit your laser diode data sheet with your quote request or with your order to get the correct mounting plate part number.

High Power TEC Based Temperature Stabilization

The laser diode heat sink is actively cooled with integrated high efficiency TEC/Peltier elements. The Peltier coolers are located below the mounting plate to remove the heat from the device under test. The fans in the heat sink dissipate the waste heat away from the load, allowing the TEC's to precisely maintain the temperature set point. The mounting plate is pre-configured for your exact package style and includes pre-tapped mounting holes as well as a graphite thermal pad to assist the heat transfer. Standard mounting hole footprint patterns for many modules and package styles. Custom mounting hole patterns are available upon request. These laser diode control systems offers a convenient and high performance solution for cooling and temperature stabilization of your device.

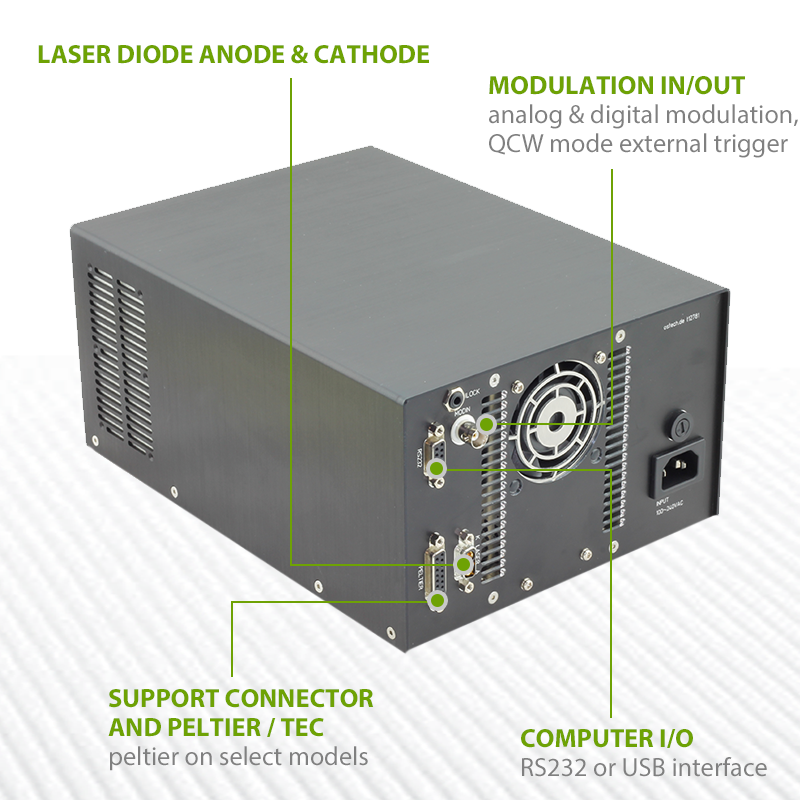

Modulation, Internal Function Generator, and QCW Pulse Modes

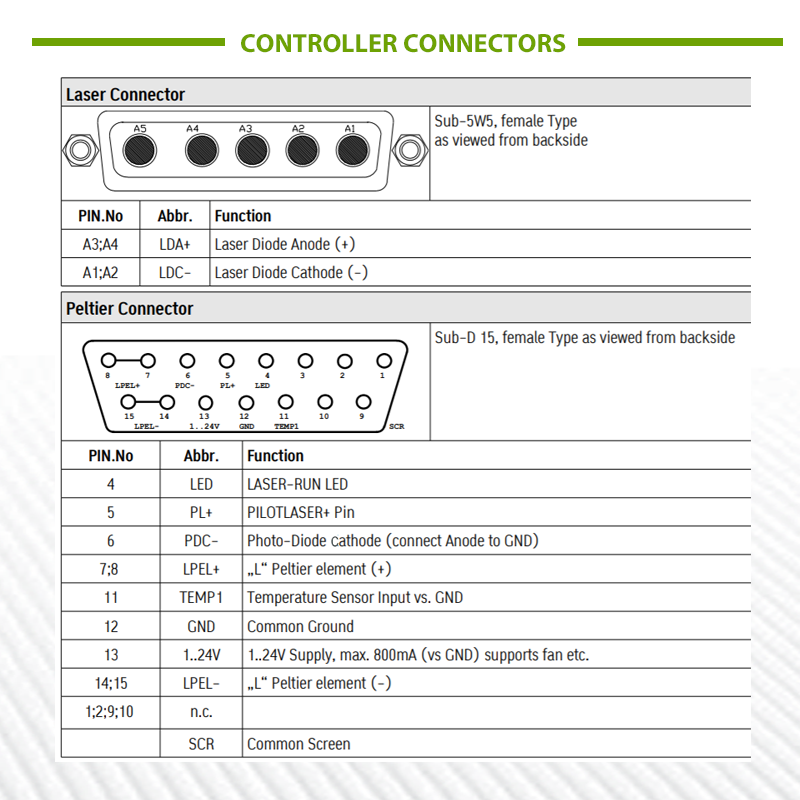

In addition to CW mode, the LDC-578X includes an internal function generator which can be used to operate the laser diode in a QCW (pulsed) mode with user-set pulse width from 15 microseconds to CW. The rear panel d-SUB connector has dedicated pins for an external modulation function generator to be applied to the bias current driving the laser.

User Interface

The user has the choice of using the standard RS232 serial interface on the rear panel, or ordering the optional USB interface ($100). After connecting the driver to a PC, the LDC-164 includes LabView drivers with a simple to use graphical user interface (GUI). All of the laser diode control parameters can be set and monitored using the GUI, including bias current set-point, current limit, slow-start current ramp time, and modulation. If the user does not have LabView, a serial command set is provided in the manual for the user to control the driver.

Why do Scientists & Engineers Choose Laser Lab Source?

-

Get DIRECT, Fast Tech-Support from the Product Engineer, No Sales Person in the Middle

-

Get the Lowest Price, Factory Direct, No Mark-Up's, Suppliers Post their Own Price

-

Get a 30 Day Evaluation Period with No Risk Return on Most Products, Check Availability