Home > Laser Diode Drivers > OsTech > LDI-823

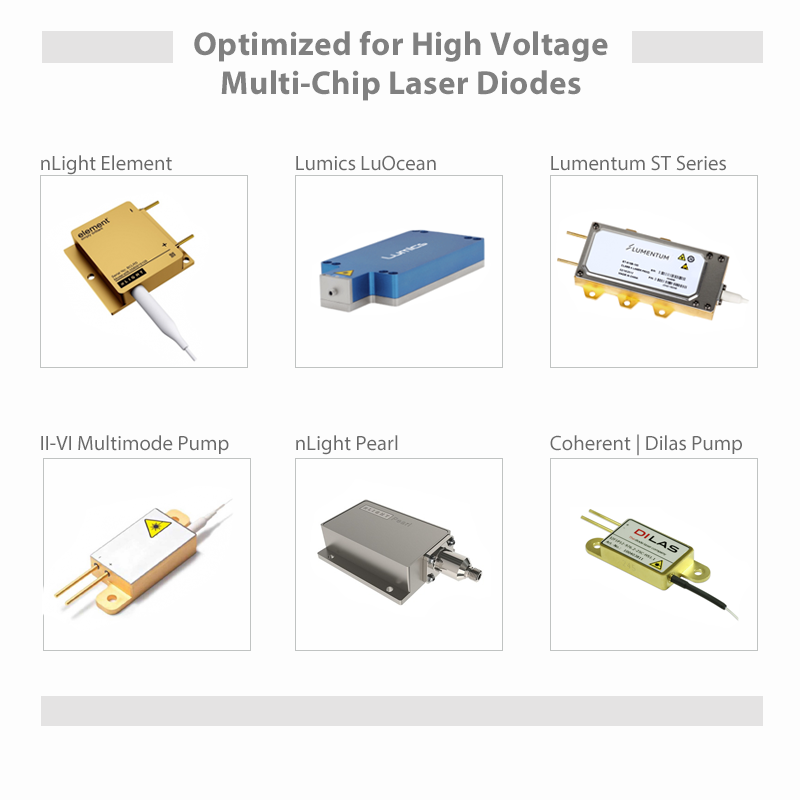

High Compliance Voltage Laser Diode Driver; Compliance Voltage Range 24 Volts; Current Range 15 Amps

$1895.00 sku / item#: LDI-823 ships: Currently Unavailable

Key Features

- Multiple protection circuits safeguard your laser diode

- Rear panel connector for feedback from external temperature sensor (ie 10K thermistor) with shut-down if laser over-temperature condition is detected

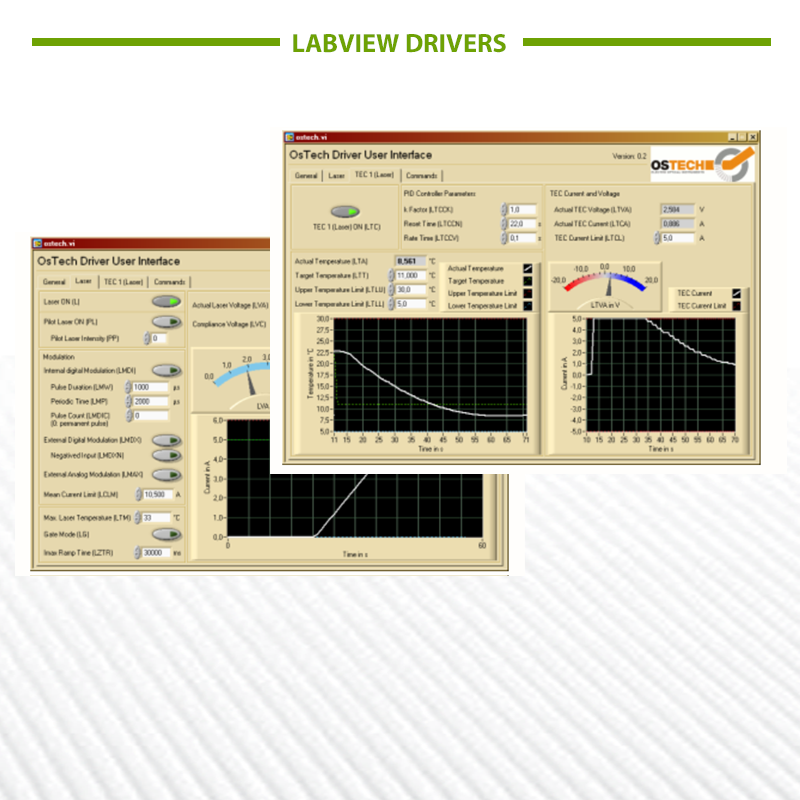

- RS232 interfaces, LabVIEW drivers

- GUI software; Python libraries and terminal control software included

- CW and Quasi-CW (QCW) modes

Product Warranty

All products purchased from Laser Lab Sourceare sold with a full one-year warranty. See terms & conditions for full details.The Laser Lab Source group websites include:- LaserDiodeSource.com

- LaserLabSource.com

- LaserDiodeControl.com

Price and Delivery Quote

Buy Now / Add to Cart

Select Cables and Accessories for this Controller

This cable is also available terminated on the

controller end with a 15-pin d-sub connector (male) and

15-pin d-sub connector (female) on the device-end (kab-231).

This cable is also available terminated on the

controller end with a 15-pin d-sub connector and

unterminated on the device-end (kab-39).

Customers Also Considered:

| MODEL | LDI-823 |

|---|---|

| PRICE | $1895.00 |

| LASER DIODE DRIVER CURRENT OUTPUT | |

|

|

| INTEGRATED LASER DIODE PROTECTION FEATURES | |

|

|

| QCW PULSE MODE AND MODULATION | |

|

|

| auxiliary functions | |

|

|

| USER INTERFACE AND CONNECTORS | |

|

|

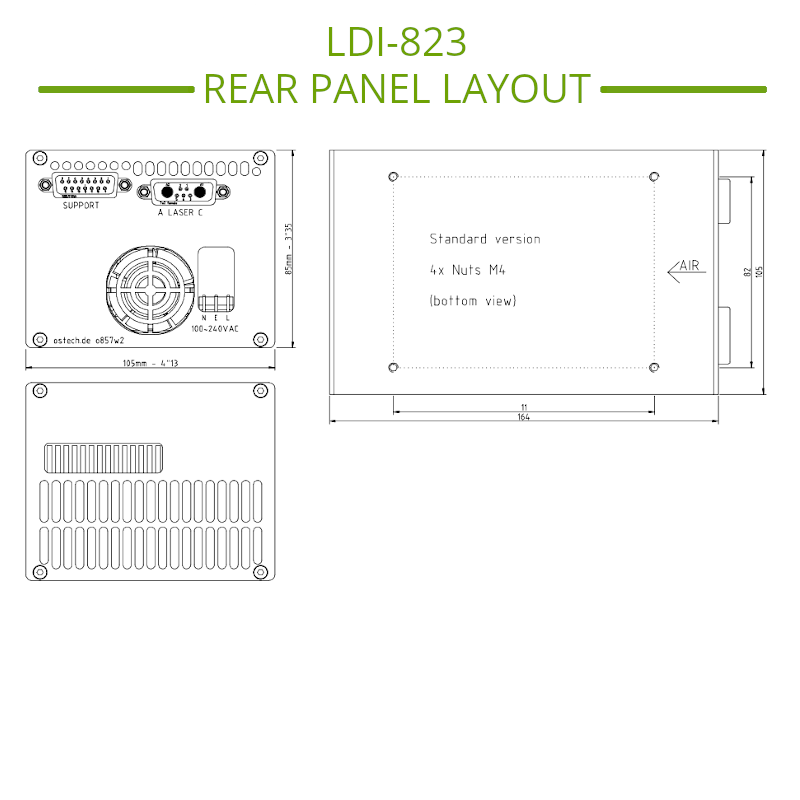

| DIMENSIONS AND power INPUT | |

|

|

| Recommended Accessories | |

|

|

Product Overview:

LDI Series Laser Diode Driver Modules

The LDI series laser diode diode drivers are precision-engineered to electrically bias high power laser diodes while protecting them from the common causes of damage which can potentially harm or destroy semiconductor lasers. Because high power lasers require relatively high levels of DC current and voltage, and generate high levels of waste heat, they have a unique set of electrical and thermal requirements which need to be addressed to protect them from being damaged. Additionally, the driver has been designed with features to assist the user to safely operate the laser diode under test.

Laser Diode Protection Features

These units offer the highest level of commercially available laser diode protection to ensure that your laser is protected from damage. Current and voltage limits, laser diode temperature limit, and a fast shut-down sequence keep your device protected at all times. The following protection features combine to safeguard your laser diode:

Constant Current Source Laser Diode Driver

The LDI series drivers are based on high stability, low-noise current source topology to ensure optimal performance from your laser diode. They provide exceptionally low drift, allowing for consistent and repeatable results. The constant current source topology is based on a precision sense resistor which is placed in series with the laser diode. The voltage across this sense resistor is fed into a differential amplifier, which compares it to the reference voltage. If the measured current deviates from the setpoint, the feedback loop adjusts the control voltage applied to the pass transistor (MOSFET). The transistor acts as a variable resistor, dynamically adjusting to maintain the desired current. The current source automatically adjusts its output voltage to meet the laser's requirements while keeping the current constant.

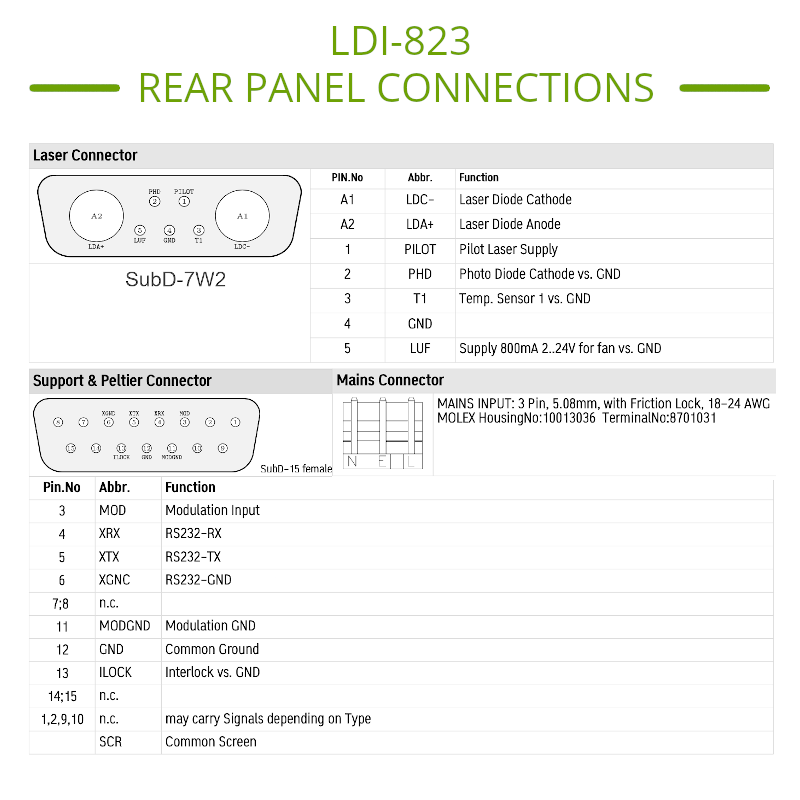

Modulation, Internal Function Generator and QCW Modes

In addition to CW (continuous wave) mode of operation, the LDI series laser diode drivers offer flexible modulation capabilities and a built-in QCW function generator. The rear panel of the controller has a BNC input for analog or TTL digital modulation inputs with a 10k Ω input impedance. The controller has an internal function generator which can be used to set the quasi-CW (QCW) pulses. In QCW mode, the user can also set QCW pulses from a remote TTL signal source or by using the internal function generator.

RS232 & USB Interfaces | Analog Signal Controls

These driver modules offer multiple user interface options. For remote control, all models come standard with a RS-232 interface and USB adapter. For all models, the LabView GUI (included) makes set-up and control of the system fast and simple. An open-source terminal software program is also available for download. The user can also control the unit using analog controls signal inputs available on the rear panel.

Why do Scientists & Engineers Choose Laser Lab Source?

-

Get DIRECT, Fast Tech-Support from the Product Engineer, No Sales Person in the Middle

-

Get the Lowest Price, Factory Direct, No Mark-Up's, Suppliers Post their Own Price

-

Get a 30 Day Evaluation Period with No Risk Return on Most Products, Check Availability